2020-07-19 09:25:00 Sun ET

distinctive capabilities value creation service innovations competitive advantages team leaders specialists advisors iterative continuous improvements senior managers core competences core business operations seamless systems blue ocean seamless integration lean solutions minimum viable products lean production lean consumption continuous flow toyota product differentiation cost leadership

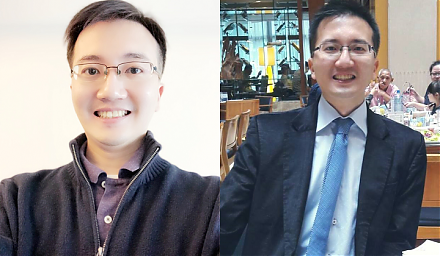

Senior business leaders can learn much from the lean production system with iterative continuous improvements at Toyota.

Takehiko Harada (2015)

Lean values and principles arise from the Toyota production system that Japanese senior engineer Taiichi Ohno gradually built in the post-war decades. The 15 main management lessons help senior business leaders, middle managers, and several other team members reduce waste in order to create the continuous flow of small batches of lean production with iterative continuous improvements over time. This lean approach helps most team members achieve the product-market fit, a delicate balance between work-life quality and employee motivation, and greater alignment between lean business processes and core value streams (the latter of which often cater to the essential customer needs and wants).

The lean CEO is the top executive manager who molds, changes, and then refines the organizational rules, functions, and key business operations. In a lean business environment, this top executive manager builds a solid and robust communication pipeline to most team members for better productivity. Senior business managers must learn to delegate critical tasks to subject matter experts by transferring major authority to the departmental supervisors. This delegation helps foster mutual trust, respect, recognition, and motivation for most team members. This mutual trust can effectively contribute to greater transparency and better regulation over time.

Specific challenges arise from the executive oversight of core business operations in foreign countries. Senior executive managers must learn the local cultures and customs with sufficient reliance on local middle managers and core team members as much as possible to integrate lean startup methods into their business functions. When push comes to shove, it is important for senior business leaders to promote better alignment between foreign value streams and lean business processes.

Senior business leaders can learn lean lessons from the Toyota production system.

The ingenious insight of Taiichi Ohno focuses on the continuous flow of both small parts and components to holistic products (or Toyota cars) with little waste of over-production. This one-piece flow becomes the Toyota production system in the lean business context. Senior business leaders can learn lean lessons from this Toyota production system:

The chief executive manager integrates several lean business endeavors with core value streams and distinctive capabilities.

The top management style and corporate culture must change for the better. The chief executive manager integrates most of the lean business processes with core value streams and distinctive capabilities. In this important way, the lean business approach differs much from the traditional management style of getting orders from senior executive committees.

The main organizational structure includes its rules, functions, and core business operations. Departmental functions designate what team members and individual contributors need to accomplish within reasonable time frames. Both functions and rules are critical business decisions on the standard work. Senior supervisors and team members carry out core business operations to pull together both individual contributions as well as collaborative efforts.

The lean CEO can change the corporate rules, functions, and business operations in response to external forces and circumstances. From time to time, such changes bring about iterative continuous improvements. The lean CEO needs to establish a robust direct communication pipeline from the key business operations to the top management team. This positive communication helps ensure alignment between critical business operations and the top management team members (who monitor delicate changes in both the external circumstances and customer demands).

Senior managers and other team members strive to sustain the continuous flow of small batches of lean production.

Both senior supervisors and team members should strive to sustain the continuous flow of small batches of lean production. These senior business leaders must build a sustainable organizational structure that empowers all team members to see how their core business operations contribute to the eventual fulfillment of bold strategic goals. Sometimes shorter-term tactical solutions help senior supervisors and most team members achieve the longer-term strategic goals in due course. In this light, senior managers and supervisors often must triangulate both business decisions and issues from alternative perspectives. For this reason, the senior management team should include top executive leaders with diverse analytic skills, backgrounds, and experiences. In essence, senior managers and supervisors need to delegate tasks well enough so that team members can carry out core business operations in accordance with the standard work priorities and long-term corporate strategies. When push comes to shove, the law of inadvertent consequences often counsels caution. Iterative continuous improvements become possible in this context.

Senior managers and supervisors cannot monitor the standard work on a continual basis. Instead, these senior managers and supervisors often need to facilitate the continuous flow of small batches of lean production. At the same time, these senior managers and supervisors need to identify new business opportunities for iterative continuous enhancements such that core business operations can change for the better. Senior managers should delegate proper authority to both supervisors and most team members to ensure relentless standardization. In-depth standards help minimize the chances of technical mistakes, setbacks, abnormalities, and so forth. The bilateral communication between senior managers and team members helps ensure better alignment between lean business processes and long-term strategic goals. In this important way, senior managers can diagnose proper solutions (but not quick fixes) in order to resolve the root causes of recurrent technical issues.

Moreover, good business leaders must often recognize the collaborative efforts of both team members and individual contributors. This recognition helps boost team morale and employee motivation. All the team members and individual contributors should be able to see the immediate results and rewards of the standard work. All team members should further feel the eventual results of positive changes that can boost output gains per unit of input factors. Iterative continuous improvements can become part of core business processes over time. These iterative improvements are both short-term tactical solutions as well as medium-term strategic solutions at the heart of lean business production.

Senior managers and key team members must adapt foreign business operations to the local cultures and customs.

Senior managers who head core business operations in a foreign country may face specific challenges. When these managers find out their international assignments, these senior executive managers should take time to visit the core business men or women who led business operations in that foreign country. This communication can allow senior managers to acquire valuable information about the local cultures, customs, rules, laws, consumer tastes, habits, lifestyles, preferences, and so forth.

From time to time, these senior managers may fall into the trap of misconceptions about foreign business operations. Many missions that senior managers may view as difficult may turn out to be quite easy, whereas, many other missions that senior managers may view as easy may turn out to be difficult or virtually impossible. For this reason, it is paramount for these senior managers to talk with their local team members to better assess difficulty levels before these managers undertake major changes in foreign business operations.

In foreign business operations, senior managers need to cultivate a healthy team environment where it is okay for team members to say sorry. Team members must be able to admit mistakes, setbacks, and disappointments with no adverse career consequences. Otherwise, some team members would choose to cover up errors at work. Senior managers must remain true and authentic to themselves and their subordinates in foreign business operations. When new issues and obstacles arise from the broader business context, senior managers would be able to work closely with their local team members to find the root causes of specific technical problems. In this unique fashion, these senior managers and local team members can better diagnose proper solutions that rectify the fundamental flaws for good. Therefore, it is important for these senior managers to focus on the root analysis of the problem rather than the literal words of the apology.

Senior managers must find suitable local middle managers to work with upstream suppliers. These local middle managers can gradually mold specific suppliers into key lean production partners. In a delicate way, these local middle managers can train most upstream suppliers to learn the continuous flow of small batches of lean production. If senior managers select multiple local middle managers, these multi-trainers may inadvertently exhibit differences in the style and substantive content of communication with upstream suppliers. Sometimes such differences can cause unnecessary confusion.

These local middle managers hence serve as upstream supplier-trainers in charge of several companies. These trainers need to visit the respective suppliers at least once per month. During these regular visits, the trainers get to know the pervasive issues of core upstream suppliers, report these issues to senior managers, receive instructions on what can constitute proper solutions, and then deploy these proper solutions at the supplier sites in accordance with the standard work priorities and longer-term strategic goals. At least once per quarter, senior managers should go with the local trainers to verify the current progression of upstream supply chains. In fact, it is quick and effective for senior managers to localize all middle managers and supplier-trainers to encourage better collaborative efforts.

This analytic essay cannot constitute any form of financial advice, analyst opinion, recommendation, or endorsement. We refrain from engaging in financial advisory services, and we seek to offer our analytic insights into the latest economic trends, stock market topics, investment memes, personal finance tools, and other self-help inspirations. Our proprietary alpha investment algorithmic system helps enrich our AYA fintech network platform as a new social community for stock market investors: https://ayafintech.network.

We share and circulate these informative posts and essays with hyperlinks through our blogs, podcasts, emails, social media channels, and patent specifications. Our goal is to help promote better financial literacy, inclusion, and freedom of the global general public. While we make a conscious effort to optimize our global reach, this optimization retains our current focus on the American stock market.

This free ebook, AYA Analytica, shares new economic insights, investment memes, and stock portfolio strategies through both blog posts and patent specifications on our AYA fintech network platform. AYA fintech network platform is every investor's social toolkit for profitable investment management. We can help empower stock market investors through technology, education, and social integration.

We hope you enjoy the substantive content of this essay! AYA!

Andy Yeh

Chief Financial Architect (CFA) and Financial Risk Manager (FRM)

Brass Ring International Density Enterprise (BRIDE) © 2013-2023

Do you find it difficult to beat the long-term average 11% stock market return?

It took us 20+ years to design a new profitable algorithmic asset investment model and its attendant proprietary software technology with fintech patent protection in 2+ years. AYA fintech network platform serves as everyone's first aid for his or her personal stock investment portfolio. Our proprietary software technology allows each investor to leverage fintech intelligence and information without exorbitant time commitment. Our dynamic conditional alpha analysis boosts the typical win rate from 70% to 90%+.

Our new alpha model empowers members to be a wiser stock market investor with profitable alpha signals! The proprietary quantitative analysis applies the collective wisdom of Warren Buffett, George Soros, Carl Icahn, Mark Cuban, Tony Robbins, and Nobel Laureates in finance such as Robert Engle, Eugene Fama, Lars Hansen, Robert Lucas, Robert Merton, Edward Prescott, Thomas Sargent, William Sharpe, Robert Shiller, and Christopher Sims.

Follow AYA Analytica financial health memo (FHM) podcast channel on YouTube: https://www.youtube.com/channel/UCvntmnacYyCmVyQ-c_qjyyQ

Follow our Brass Ring Facebook to learn more about the latest financial news and fantastic stock investment ideas: http://www.facebook.com/brassring2013.

Free signup for stock signals: https://ayafintech.network

Mission on profitable signals: https://ayafintech.network/mission.php

Model technical descriptions: https://ayafintech.network/model.php

Blog on stock alpha signals: https://ayafintech.network/blog.php

Freemium base pricing plans: https://ayafintech.network/freemium.php

Signup for periodic updates: https://ayafintech.network/signup.php

Login for freemium benefits: https://ayafintech.network/login.php

If any of our AYA Analytica financial health memos (FHM), blog posts, ebooks, newsletters, and notifications etc, or any other form of online content curation, involves potential copyright concerns, please feel free to contact us at service@ayafintech.network so that we can remove relevant content in response to any such request within a reasonable time frame.

2018-07-19 18:38:00 Thursday ET

Goldman Sachs chief economist Jan Hatzius proposes designing a new Financial Conditions Index (FCI) to be a weighted-average of interest rates, exchange rat

2019-02-09 08:33:00 Saturday ET

Apple provides positive forward guidance on both revenue and profit forecasts for iPhones, iPads, and MacBooks. In the Christmas 2018 festive season, MacBoo

2018-11-21 11:36:00 Wednesday ET

Apple upstream suppliers from Foxconn and Pegatron to Radiance and Lumentum experience sharp share price declines during the Christmas 2017 holiday quarter.

2019-03-29 12:28:00 Friday ET

Federal Reserve Chair Jerome Powell answers CBS News 60 Minutes questions about the recent U.S. economic outlook and interest rate cycle. Powell views the c

2020-11-22 11:30:00 Sunday ET

A brief biography of Andy Yeh Andy Yeh is responsible for ensuring maximum sustainable member growth within the Andy Yeh Alpha (AYA) fintech network pla