2020-07-12 08:30:00 Sun ET

lean startup team work streams best practices value creation service innovations customer-centric metrics team leaders iterative continuous improvements culture changes senior managers core business operations seamless systems blue ocean seamless integration lean solutions lean production lean consumption continuous flow toyota product differentiation cost leadership meritocracies critical success factors

The lean CEO encourages iterative continuous improvements and collaborative teams to innovate around core value streams.

Jacob Stoller (2015)

The lean CEO: leading the way to world-class excellence

The lean CEO strives to minimize the corporate dependence on traditional financial statements and standard accounting practices. The lean CEO and his or her teams structure the broader business organization around value streams with lean startup techniques and iterative continuous improvements. Lean business organizations identify and eliminate waste in order to build up capacity without substantial capital expenditures. This lean startup method empowers senior business leaders to curb time-invariant recurrent costs (such as rent and personnel) for better organizational resilience during rare hard times of financial stress.

From time to time, the lean CEO and his or her senior management teams should adopt a realistic approach to talent retention and motivation. Many traditional work places experience low employee morale and engagement, whereas, lean business organizations offer effective and collegial team environments that encourage most employees to sharpen the saw through iterative continuous improvements in terms of mistakes, setbacks, and even epic failures. In lean business organizations, the CEO, his or her direct reports, and other team members act in good faith with trust and respect for others. The lean CEO tends to instruct senior executive managers to break down organizational silos in favor of core value streams. In essence, the lean CEO highly values his or her team members and so seeks to remove all major barriers that may deter employees from reaching their greatest potential. At Toyota, senior engineers can go through several stages of gradual career progression to take up new managerial responsibilities to pass on institutional knowledge. In turn, this institutional knowledge helps reinforce the close alignment between core value streams and lean production processes.

The lean startup method is a new radical approach to continuous production.

Toward the end of World War II, much of Japanese industrial capability had been destroyed. At the Toyota Motor Company, the young engineer Taiichi Ohno began thinking about how Toyota could catch up with American car producers. In light of the essential need for waste minimization in the manufacturing system, Ohno built a lean production system of continuous flow, which permitted product progression through lean production with no interruption. At Toyota, this lean production system met customer demands for cost-effective and affordable Japanese cars and further reduced excessive inventory to the absolute minimum.

Ohno encouraged supervisors to become coaches who were able to remove entry barriers. As Ohno redefined work and time management, such supervision helped Toyota workers improve their lean production processes. The new configurations required Toyota workers to complete multiple tasks. If Toyota workers were unable to complete their tasks within the specific time slots due to safety concerns, these workers were responsible for resolving the technical issue on the spot. In the rare scenario where the workers were unable to rectify the problem, Toyota would shut down the entire lean production line until the supervisors had a chance to resolve the technical issue. Ohno used a variety of visual cues such as cards, whiteboards, color codes, and lights to manage the lean production environment so that he was able to synchronize each incremental step of the lean production. This visualization allowed for greater transparency and better regulation.

In order to produce multiple models within specific time frames, Toyota engineers had to change the lean production lines quickly from one model to the next. Ohno designed a changeover process that broke down the lean production process into small components. In this important way, Toyota engineers and workers were able to complete as much of the work as possible as the major equipment continued to run in parallel. Iterative continuous enhancements became possible over time.

From a fundamental viewpoint, Ohno came up with the ingenious insight of treating upstream suppliers as key production partners. When Toyota cut back on inventory, the company could no longer accept large orders from its suppliers. Toyota played an active important role in helping suppliers conform to delivering smaller batches so that Toyota could better align a steady flow of orders with the internal continuous flow of lean production processes. In this important way, Toyota connected global supply chains to the internal continuous flow of small batches of lean production.

Ohno introduced the concept of lean value streams. Lean value streams were end-to-end representations of all the steps toward fulfilling customer needs and wants. Each value stream depicted how several diverse entities combined to create value within the Toyota production system. Toyota supervisors and engineers structured resources, funds, and direct reports etc around these lean value streams. Through many years of both hard work and discipline from all Toyota workers, Ohno came to the realization that lean production should be a continuous journey with no end. This realization further reinforced the crucial notion of continuous flow around lean value streams throughout the Toyota production system.

Ohno developed the lean production principles at Toyota in the 1950s, but these principles became well-known ubiquitous in America and elsewhere much later in the 1980s. In the 1980s, both the American and European manufacturers struggled to streamline their mass production of cars, boats, airplanes, electronic appliances, and so forth. In the late-1980s, several former Japanese Toyota senior managers launched a management consultancy firm to bring the lean production methods to many other companies worldwide. Within 5 years, key enterprise-wise productivity gains reached 85%. By the mid-1990s, many multinational manufacturers adopted the lean production methods for better waste minimization and profit maximization.

The lean startup method is a new way out of corporate financial distress.

The lean production methods originated as a series of novel measures that Toyota applied to turn around the bleak post-war economic situation. These lean methods allowed Toyota to dramatically improve its capacity and productivity when the auto company was unable to invest in new resources. From the mid-1950s to the 1970s, Toyota managed to eliminate substantial amounts of obvious waste. Also, the lean production methods empowered both the American and European manufacturers to survive economic crises from the 1980s to the mid-1990s. Nonetheless, the lean production methods required significant changes in how the CEOs and their senior management teams thought about financial cost structures.

Traditional manufacturers relied heavily on financial statements and standard cost accounting practices to identify waste, whereas, lean CEOs came to the realization that most financial reports failed to offer the up-to-date information with actionable business insights. In this negative light, it was difficult for lean CEOs to make good day-to-day managerial decisions on the solo basis of financial statements (such as balance sheets, income statements, and cash flow statements). From time to time, financial reports might understate the severity and duration of imminent economic threats. At the same time, standard cost accounting practices might inadvertently obscure the fine line between time-invariant recurrent costs and variable costs. In summary, this stale financial information might all lead to poor business decisions about waste minimization and profit maximization.

In order to remove most of the deep entry barriers to lean transformation, the CEOs must allow the lean startup culture to fully take hold throughout their organizations. The most important prerequisites for successful lean transformation include 100% senior management commitment, lean evaluation of both costs and benefits within each core value stream, and long-haul reorganization around core value streams. Senior business leaders, middle managers, and other team members need to learn new skills to understand how the lean production methods cater to most customer needs and wants for better economic value extraction with no or little waste.

The lean production methods focus on identifying opportunities for team members to reduce waste in the broader business environment. Through iterative continuous improvements, lean enterprises can manage to free up significant amounts of plant space, equipment, and employee work time etc. The resultant lean business model helps reduce organizational reliance on time-invariant recurrent costs. In turn, this lean business approach boosts organizational resilience in both normal times and major economic downturns. Freeing up employee work time can further lead to an overall increase in worker morale and motivation.

There is a common workforce motivation problem in many traditional companies. In this business context, many workers cannot earn trust, respect, and recognition in these traditional workplaces. Corporate policies, bureaucratic rules, managerial relations, and basic work conditions etc often demotivate team members with poor employee morale, low productivity, subpar process quality, and even outrage and hostility toward senior business leaders and managers.

Lean CEOs build up the ideal business environment for greater worker motivation. Autonomy, recognition, variety, and the opportunity to learn new skills are intrinsic rewards that motivate most team members to retain their active interest in the lean organizational culture of iterative continuous improvements. In order to encourage most team members to reach their greatest potential, lean CEOs often come to the realization that senior managers must remain true and authentic through the lean business processes. Direct managerial involvement helps senior business leaders listen to their direct reports and other team members. In this critical way, most team members receive positive comments and guidelines that empower these workers to perform their day-to-day tasks and jobs.

The lean startup method adds value to great teamwork and employee morale.

In lean business organizations, an important pillar for great teamwork and worker morale is respect for people. Both middle managers and team members need clear guidance on their day-to-day business activities. Senior business leaders need to empower these middle managers and their key men and women with the right tools, skills, and processes to perform well in due course. In this light, proper delegation is essential in most lean business organizations. Middle managers, supervisors, or most other team members can count on their senior business decision-makers to help remove any barriers that stand in their way. From time to time, senior business leaders must cultivate a comprehensive culture change to strike a delicate balance between top-down autocratic management and bottom-up democratic execution. Sometimes lean CEOs must learn to implement sustainable idea meritocracies (in the wise words of Bridgewater hedge fund founder Ray Dalio). One of the toughest tasks for lean CEOs entails designing a positive business environment where both middle managers and most other team members can succeed in their current jobs. In effect, this design brings about positive predictable business outcomes.

Another important challenge for lean CEOs involves breaking down organizational silos. Silos sometimes support individual or even group interests at the expense of the whole business organization. These silos are often one of the most destructive forces in the broader business context. When sections, divisions, departments, or individual contributors cannot share with one another and middle managers cannot pull together core competencies and collaborative efforts, the entire organization ceases to operate as a great cohesive team. Without cross-functional cooperation, it is almost impossible for lean CEOs to boost profits with lower costs around core value streams.

Lean CEOs must put their people first. In the broader business context, most team members should be able to learn institutional knowledge via lean transformations. Such lean transformations focus on customer-centric value creation, core business design and development around value streams, and waste minimization. After all, lean CEOs should strive to remove any barriers that prevent most team members from reaching their highest potential. Lean CEOs often encounter the cost-quality conundrum: senior business leaders circumvent an inexorable deterioration in both product and service quality as their team members strive to minimize costs. In this unique fashion, both cost leadership and product differentiation become essential to iterative continuous improvements throughout the lean business organization.

Lean business organizations often beat their competitors by acquiring institutional knowledge fast enough to adapt to external forces and conditions. In this context, prescient teamwork requires core engagement, keen observation, and meritocracy in pursuit of both short-term tactical solutions and longer-term strategic goals. Lean business principles support and promote this prescient teamwork above all else as most team members learn from their collaborative efforts, ideas, tasks, and jobs.

Lean CEOs must encourage most team members to share both their generic and institutional knowledge. All team members should remain open and positive toward the creative ideas, views, and opinions of subject matter experts. Lean CEOs need to offer clear guidelines and suggestions for both middle managers and most other team members to perform well amid considerable economic policy uncertainty and product quality heterogeneity. In essence, lean CEOs should be assertive enough to empower people to find their own solutions. This idea meritocracy maintains a simultaneous balance between great teamwork and worker morale.

Lean CEOs encourage both iterative continuous improvements and collaborative teams to innovate around core value streams. Lean business team members strive to minimize the corporate dependence on traditional financial statements and cost structures. Lean CEOs and their teams build up the broader business organization and capacity around core value streams. This lean production method focuses on the key lessons that most team members can learn from mistakes, setbacks, and even epic failures etc. Lean business organizations identify and eliminate waste in order to build capacity without large capital expenditures. This lean startup method empowers senior business decision-makers to curtail high time-invariant recurrent costs (such as rent and personnel) for better organizational resilience during rare hard times of financial stress.

In brief, we can sum up the key lessons from lean business production at Toyota. First, the lean startup method is a new radical approach to continuous production. Second, the lean startup method is a new way out of corporate financial distress. Third, the lean startup method adds value to great teamwork and employee morale. As senior business leaders and decision-makers delve into demographic data for better assessing the latest trends of customer needs and wants, lean CEOs should structure team resources around core value streams to cater to these clear trends. Many lean business organizations need to undertake a major dual transformation. On the one hand, these companies should focus on applying proprietary methods to perform in-house the vast majority of core competencies, critical functions, and distinctive capabilities etc. On the other hand, these companies should also keep overhead costs low by outsourcing several non-core business functions. As these lean enterprises phase out this dual transformation, new proprietary methods can help perform the core business functions in-house in a more efficient manner when the critical business resources, processes, and values help perform at least some of the non-core business functions in a more cost-effective way. Overall, this dual transformation can help incubate hybrid disruptive innovations through the typical business lifecycle.

From time to time, the lean CEO and his or her senior management teams should adopt a realistic approach to talent retention and motivation. Many traditional work places experience low employee morale and engagement, whereas, lean business organizations offer effective and collegial team environments that encourage most employees to sharpen the saw through iterative continuous improvements in terms of mistakes, setbacks, and even epic failures. In lean business organizations, the CEO, his or her direct reports, and other team members act in good faith with trust and respect for others. The lean CEO tends to instruct senior executive managers to break down organizational silos in favor of core value streams. In essence, the lean CEO highly values his or her team members and so seeks to remove all major barriers that may deter employees from reaching their greatest potential. At Toyota, senior engineers can go through several stages of gradual career progression to take up new managerial responsibilities to pass on institutional knowledge. In turn, this institutional knowledge helps reinforce the close alignment between core value streams and lean production processes.

This analytic essay cannot constitute any form of financial advice, analyst opinion, recommendation, or endorsement. We refrain from engaging in financial advisory services, and we seek to offer our analytic insights into the latest economic trends, stock market topics, investment memes, personal finance tools, and other self-help inspirations. Our proprietary alpha investment algorithmic system helps enrich our AYA fintech network platform as a new social community for stock market investors: https://ayafintech.network.

We share and circulate these informative posts and essays with hyperlinks through our blogs, podcasts, emails, social media channels, and patent specifications. Our goal is to help promote better financial literacy, inclusion, and freedom of the global general public. While we make a conscious effort to optimize our global reach, this optimization retains our current focus on the American stock market.

This free ebook, AYA Analytica, shares new economic insights, investment memes, and stock portfolio strategies through both blog posts and patent specifications on our AYA fintech network platform. AYA fintech network platform is every investor's social toolkit for profitable investment management. We can help empower stock market investors through technology, education, and social integration.

We hope you enjoy the substantive content of this essay! AYA!

Andy Yeh

Chief Financial Architect (CFA) and Financial Risk Manager (FRM)

Brass Ring International Density Enterprise (BRIDE) © 2013-2023

Do you find it difficult to beat the long-term average 11% stock market return?

It took us 20+ years to design a new profitable algorithmic asset investment model and its attendant proprietary software technology with fintech patent protection in 2+ years. AYA fintech network platform serves as everyone's first aid for his or her personal stock investment portfolio. Our proprietary software technology allows each investor to leverage fintech intelligence and information without exorbitant time commitment. Our dynamic conditional alpha analysis boosts the typical win rate from 70% to 90%+.

Our new alpha model empowers members to be a wiser stock market investor with profitable alpha signals! The proprietary quantitative analysis applies the collective wisdom of Warren Buffett, George Soros, Carl Icahn, Mark Cuban, Tony Robbins, and Nobel Laureates in finance such as Robert Engle, Eugene Fama, Lars Hansen, Robert Lucas, Robert Merton, Edward Prescott, Thomas Sargent, William Sharpe, Robert Shiller, and Christopher Sims.

Follow AYA Analytica financial health memo (FHM) podcast channel on YouTube: https://www.youtube.com/channel/UCvntmnacYyCmVyQ-c_qjyyQ

Follow our Brass Ring Facebook to learn more about the latest financial news and fantastic stock investment ideas: http://www.facebook.com/brassring2013.

Free signup for stock signals: https://ayafintech.network

Mission on profitable signals: https://ayafintech.network/mission.php

Model technical descriptions: https://ayafintech.network/model.php

Blog on stock alpha signals: https://ayafintech.network/blog.php

Freemium base pricing plans: https://ayafintech.network/freemium.php

Signup for periodic updates: https://ayafintech.network/signup.php

Login for freemium benefits: https://ayafintech.network/login.php

If any of our AYA Analytica financial health memos (FHM), blog posts, ebooks, newsletters, and notifications etc, or any other form of online content curation, involves potential copyright concerns, please feel free to contact us at service@ayafintech.network so that we can remove relevant content in response to any such request within a reasonable time frame.

2018-02-23 09:35:00 Friday ET

Warren Buffett releases his annual letter to Berkshire Hathaway shareholders as of February 2018. Buffett discusses Berkshire's core cash ambition, its

2023-02-28 11:30:00 Tuesday ET

The Biden Inflation Reduction Act is central to modern world capitalism. As of 2022-2023, global inflation has gradually declined from the peak of 9.8% d

2017-12-17 11:41:00 Sunday ET

Warren Buffett points out that it is important to invest in oneself. Learning about oneself empowers him or her to lead a meaningful life. This valuable inv

2017-03-27 06:33:00 Monday ET

Goldman Sachs chief economist Jan Hatzius says the Federal Reserve's QE exit strategy makes sense ahead of Fed Chair Janet Yellen's stepdown in 2018

2023-10-07 10:24:00 Saturday ET

Thomas Philippon draws attention to greater antitrust scrutiny in light of the rise of market power and its economic ripple effects. Thomas Philippon (20

2018-03-03 11:37:00 Saturday ET

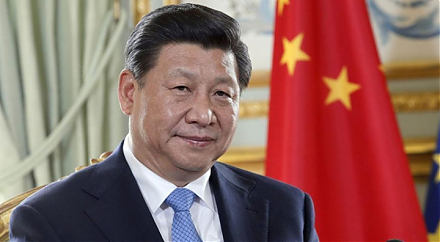

President Xi seeks Chinese congressional approval and constitutional amendment for abolishing his term limits of strongman rule with more favorable trade de